Category

High Precision Flexible Normal Abrasive 115 mm Grinding Disc Practical and Efficient Polishing Wheel

High Precision Flexible Normal Abrasive 115 mm Grinding Disc Practical And Efficient Polishing Wheel DESCRIPTION Saclion

Basic Info

| Material | Alumina |

| Abrasive | Normal Abrasive |

| Shapes | Edge Shape |

| Types | Surface Grinding Wheel |

| Grain Size | Customized |

| Cylindricity | <1 |

| Circular Degree | <1 |

| Technics | Sinter |

| Working Style | Surface Grinding |

| Model Name | Polishing Grinding Wheel |

| Type | Abrasive Disc |

| Certificate | ISO9001 MPa En12413 |

| Place of Origin | Hebei,China |

| Shape | Type 27 |

| Transport Package | Parper Cartons |

| Trademark | SACLION |

| Origin | China |

| HS Code | 6804221000 |

| Production Capacity | 500000/Month |

Product Description

High Precision Flexible Normal Abrasive 115 mm Grinding Disc Practical And Efficient Polishing Wheel| Name: | Grinding Wheel |

| Size Range: | 4" - 9" |

| Thickness Range: | 040" - 1/4" |

| Abrasive Grain: | Ceramic Alumina, Diamond, Zirconia Alumina, Aluminum Oxide, Silicon Carbide |

| Shape: | Type 27 |

| Mounting Options: | Plain hole (3/8", 5/8" and 7/8") and discard mount (5/8"-11) |

| Applications: | Grinding, stock removal, edge chamfering, beveling, weld blending, and cutting-off |

Saclion Depressed center grinding wheels may also be referred to as raised hub wheels or by their shape designation of "Type", with Type 27 being the most popular. The depressed center design allows the flange/lock nut to recess within the wheel so that it can be used for various grinding and cutting applications. Depressed center wheels are designed to handle the most severe right angle grinding applications from heavy stock removal to rough blending. More recently, depressed center wheels have been designed to increase the utility of the tool for cut-off applications. While large right angle grinders (7" & 9") have been around for many years, small or mini grinders that handle 4", 4-1/2", 5", and 6" wheels have made this machine, and wheel category, the most popular in power tools. Our products are divided into 3 lines: Economic Line, Professional Line and Premium Line. All items listed, if no other specifications, are within the Professional Line. If you need other quality levels, please do not hesitate to contact us.Quality aluminum oxide abrasive designed for cutting alloys, steels and ferrous metals including 400 series stainless, soft and hard carbon steels

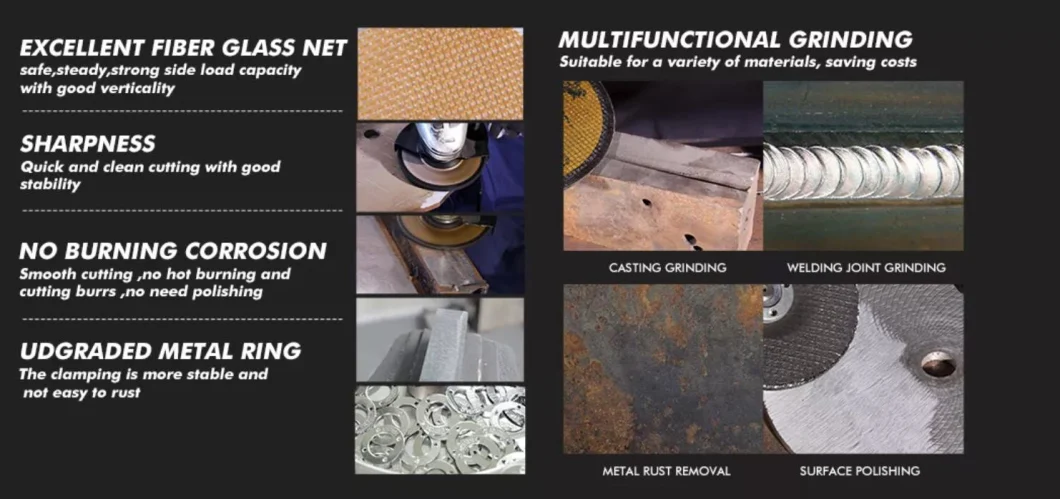

ADVANTAGES

- For soft and hard aluminium and other non-ferros metals.

- Extreme high grinding performance. Contains no fillers which might leave undesirable surface residu.

- The workpiece can be welded right away, without any further treatment.

- For surface grinding, welding seam grinding and welding edges.

- Already a good result with a low pressure.

- For angle grinders in all power ranges.

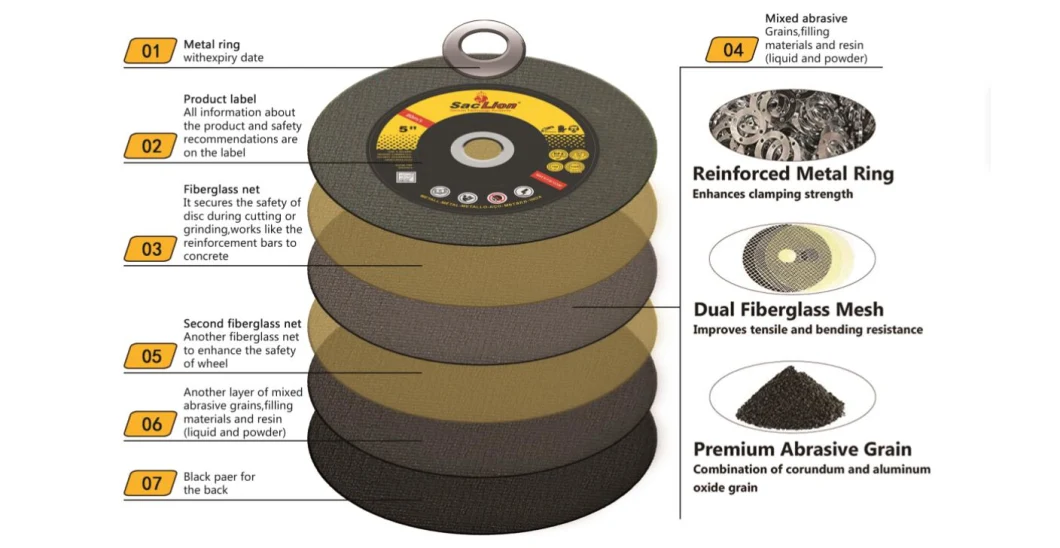

DISC STRUCTION ILLUSTRATION (GENERAL)

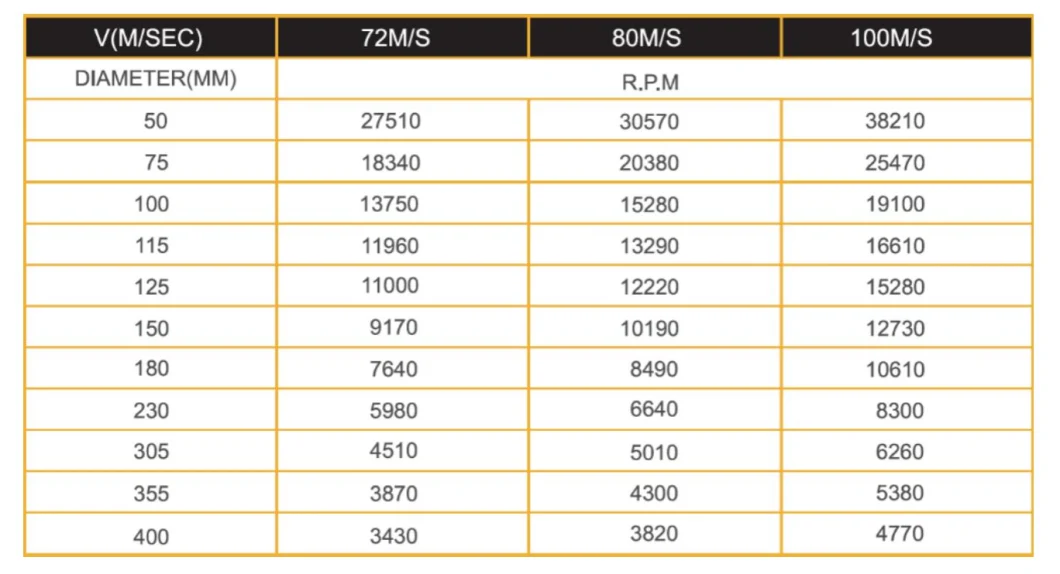

MAXIMUM PERMISSIBLE WORKING SPEED VS. R,P,M

Yuguan Abrasive Co.,ltd located Dacheng, Hebei Province (2 hours drive from Beijing) ,which specialized in reinforced resin bonded abrasive cutting and grinding discs. In the past decade, with our solid foundation in the abrasive wheels industry and our knowledge in the greater industry of hardware and tools, we have expanded our production and product lines to different fields, including flap discs, fiber discs, diamond tools, clean and strip discs etc. Yuguan Abrasives has more than 300 skilled employees, and has a production capacity of 500,000 pcs per day. Our wheels feature thicknesses in the range of 1.0mm to 10mm, and diameters of 2" to 16". All of our products adopt and meet German UVV-BGV D12 standard and we have been granted MPA (German) certification. Factory′s production and management has always been conducted in accordance with ISO9001 Certificate. Over 20 years′ working experiences has enabled our factory to maintain sustainable quality and satisfy all kinds of customers. Detailed-oriented, advanced machinery and hi-tech engineering, help us to increase the market shares year by year. The products are widely applied in mechanical processing, automobile manufacturing, shipbuilding, and stainless steel processing. Since we have established our own Brand Saclion, a whole range products, including hand tools, all kind of abrasives tools will be included from time to time.Our mainly target on the professional market for Europe and North American, and our products have been exported to Middle East, South American, Africa and totally more than 40 countries, and have been won the trust and praise of the users deeply. With advanced equipment and technique, skilled workers, and the concept of "excellent service, excellent quality, and reasonable prices", our company is opening the door for any customer all over the world. We would like to establish a very good friendship with you. As a leading and professional abrasive wheel producing, we believe we'll be your ideal choice!

Q1: Are you a trading company or manufacturer? A1: We are manufacturer of cutting & grinding wheel over 20 years, located in Dacheng ,HebeiQ2: What's your application for cutting & grinding discs? A2: Used for metal, stainless steel, carbon steel, cast iron, stone and so on.

Q3: What package do you use? accept OEM order? A3: We usually packing as shrink + neutral inner box + standard export carton, we also accept OEM order, label and package as customers' requirements.Q4:Can you provide free samples? Are samples available for quality test?A4:Yes, we can provide free samples, samples can be prepared for quality test.However, shipping cost should be paid at your account.Q5.How could you ensure the quality?A5:Only high quality and stable batch products can ensure user's safety and consistent effect.To ensure this,all our products will pass the semi-product testing,finished-product testing and inspection before delivering.Quality passes only after 3 times testing.Q6: How long is delivery time? A6: Around 20-30 days after confirmed order.